Offer

Additional information

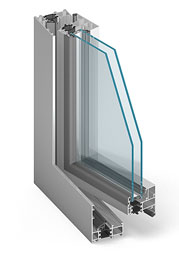

MB-59S

The MB-59S system is intended for realisations requiring thermal and acoustic insulation of the exterior building elements, such as: various types of windows, doors, vestibules, display windows, etc. The structural depth of the window sections is equal to 50 mm for frames and 59 mm for casements. The external surfaces of these sections lie in one surface. The structural depth of the door sections both for frames and the leafs is equal to 50 mm. This enables achieving the effect of facing the leaves with frames both from the external and the internal side.

Almost all window and door sections have a three-chamber structure, where the central chamber is the insulation chamber between thermal breaks. Thanks to such a solution it was possible to obtain slender, economical and rigid profiles. The system of connections with thermal break allows application of double-colour profiles - different on the internal and the external side of the façade. In MB-59S system, there are profiled "omega"-shaped thermal breaks, made from polyamide reinforced with fibreglass. Such a shape of thermal breaks ensures very good thermal insulation and the proper drainage from internal chambers of the profile.

The MB-59S system profiles meet the thermal requirements for material group 2.1 according to DIN 4108. Thickness of the in-fill material used therein may range from 4 mm to 40 mm in window casements, while in doors, displays and in fixed window: from 4 mm to 31 mm.

One of the basic advantages of MB-59S system is the freedom of selecting the hardware and methods of its mounting. Thanks to the applied special grooves, the door profile structure allows mounting various types of hinges, the co-called mortise hinges as well as fasteners and bolts. The door can be also outfitted with traditional surface hinges. The window sections have profiled grooves of dimensions allowing application of enveloped hardware and connecting elements in accordance with the European Union standards, intended both for aluminium and plastic windows. These solutions allow mounting the hardware produced by a majority of reputable companies.

The significant quality of the presented structure is the possibility to bend profiles and to achieve various types of arches and arch structures.

MB-59SE

The system of thermally-insulated economic doors MB-59SE.

The MB-59SE is a part of window/door MB-59S system. The structural depth of the section is equal to 50 mm. The applied materials and solution guarantee achieving high technical parameters: very good thermal insulation, high tightness against water and air, and also allow shortening the production and mounting time. It is possible to mount the standard hardware of reputable companies therein.

The MB-59SE structure is characterised by a low value of the heat transfer coefficient U – profiles fulfil thermal requirements for the material groups 2.1 or 2.2 according to DIN 4108. The system allows application of the set of glass panels of the thickens equal to 4.5 mm or 31.5 mm. The products based on this system passed numerous tests according to EN standards achieving very good results.

MB-60

MB-60 is a modern aluminium system intended for realizations of exterior architectural building elements requiring thermal and acoustic insulation, such as: various types of windows, doors, vestibules, display windows or spatial structures.

The system profiles have a three-chamber structure. The structural depth of the window sections is equal to 60 mm (frames) and 69 mm (casements), and for doors 60 mm and 60 mm, respectively. Such assumed depths of casement and frame sections give the effect of one surface from the exterior side after closing - in the case of the window, and the facing effect to the surfaces of casement and the frames - in the case of doors. Shape of the profiles allows achieving slender and resistant window and door structures.

There exists a possibility to bend profiles, such as frames, casements and lacings what allows achieving various types of arches and arch structures.

The MB-60 system is characterised by a low value of the overall heat-transfer coefficient U, thanks to application of the thermal breaks and gaskets. This system profiles meet the thermal requirements for the material group 2.1 in the case of windows, and 2.2 in the case of doors according to DIN 4108. In the systems, there are profiled "omega"-shaped thermal breaks applied of the width equal to 24 mm (windows) and 14 mm (doors) made from polyamide reinforced with fibreglass. Shape of the breaks increases the rigidity of profiles as compared to flat breaks, and also facilitates section drainage, ensuring the appropriate thermal insulation in all atmospheric conditions at the same time. The threshold made of HPVC and the EPDM gaskets guarantee good thermal insulation of the door leaves as well as air and water tightness.

The characteristic feature of this system is its close relation to the window/door MB-45, MB-59S and MB-70 systems. Adapting such a constructional design allowed achieving and applying many compatible elements in these systems, e.g. common glazing beads, corner joints, sealing strips, glazing and closing gaskets, common hardware, closing devices, hinges, and many identical technological processes such as pinning of connecting elements of lacings and crossbars, gluing corners joints, cutting out various recesses, etc. One of the effects of this standardization is that both the external and the internal appearance of the products such as windows, doors, etc. produced with various exterior and interior building systems are almost identical.

The MB-60 system serves as a base for solutions with an improved thermal insulation: MB-60HI, MB-60US HI, MB-60E HI, MB-60EF HI.

MB-60US

The MB-60 Hidden Casement system is a part of the window/door system with a thermal break MB-60. The windows produced from the elements of this system have casements that are unseen from the external side of the building. In the row of adjacent fixed and openable windows all the compartments look the same form the outside . The width of window frames from the external side is small, what makes the structure look slender and light.

Each window built with the MB-60 US system, destined for mounting in the exterior building, must be provided with the effective water drainage and ventilation system from the glass chamber and from the chamber between casement and the frame. The ventilation and drainage holes are covered from the outside with caps made of plastics.

Each window built with the MB-60 US system, destined for mounting in the exterior building, must be provided with the effective water drainage and ventilation system from the glass chamber and from the chamber between casement and the frame. The ventilation and drainage holes are covered from the outside with caps made of plastics.

The characteristic feature of the system is its close connection with the other systems of ALUPROF S.A. Adapting such a design allowed achieving and applying many common elements, e.g. common glazing beads, corner joints, sealing strips, glazing and closing gaskets, common hardware and many identical technological processes such as pinning of connecting elements of lacings and crossbars, gluing corners joints, cutting out various recesses, etc.

This is a version of the system with an improved thermal insulation: MB-60US HI. The improved thermal insulation is obtained by placing special inserts in the central chambers of aluminium profiles. Owing to a low value of the heat-transfer coefficient, the inserts decrease heat transfer through the construction and simultaneously reduce convection and thermal radiation in them.

MB-60E

MB-60E - cost-effective door system with a thermal barrier

The MB-60E system is intended for execution of doors with a thermal barrier as well as window sets incorporating a door unit. It allows to obtain a construction featuring good functional properties combined with high technical parameters, ensuring at the same time cost efficiency of production, convenience and shorter time required for door installation, which is of prime importance in the times when so much emphasis is put on economy at each stage of investment realization.

The MB-60E system is a part of a popular and generally appreciated MB-60 door & window system. A characteristic feature of the system is its close compatibility with other door & window systems manufactured by ALUPROF S.A., which enables utilization of common accessories and glazing beads. The construction depths of profiles, featuring 3-chamber construction, equals 60 mm. The surface of leaves is aligned with the door frame both as seen from the outside and inside. The glazing units to be incorporated in the MB-60E system may range from 5 mm to 41 mm. Pre-cut gaskets applied in glass panels installation reduce to a minimum the number of trims and ensure high tightness.

The systems can accommodate standard hardware, locks and hinges, normalized under European standards. Due to properly constructed profiles they can come with surface-mounted locks and bolts, which are quick to fit and easy to replace. The offer also includes a wide variety of thresholds and bottom crosspieces for door leaves. Notwithstanding cost efficiency of the MB-60E solution, its thermal insulation performance in no way gives way to the base system MB-60. Its additional advantage is the possibility of bending profiles, which allows performance of different arches and arched constructions.

The MB-60E system showcases can be made in a version with an improved thermal insulation: MB-60E HI. The improved thermal insulation is obtained by placing special inserts in central chambers of aluminium profiles of window frames and lacings. Owing to a low value of the heat-transfer coefficient, the inserts decrease heat transfer through the construction and simultaneously reduce convection and thermal radiation in them.

MB-60HI

In response to the ever-growing demand for building products with a high thermal insulation value, the MB-60HI, MB-60US HI, MB-60E HI and MB-60EF HI window systems with a thermal barrier have been developed. Their construction is based on the proven and tested, expanded and valued base MB-60, MB-60US, MB-60E and MB-60EF systems.

For the constructions of the MB-60HI system, the overall heat-transfer coefficient Uf amounts to from 1.48 W/(m2*K) depending upon the profiles and accessories used.

Thermal insulation is improved by placing special inserts in the central chambers of aluminium profiles. Owing to a low value of the heat-transfer coefficient, the inserts reduce heat transfer through the construction. The central location of the inserts also reduces heat transfer by convection and thermal radiation.

Similarly as for the base system, the MB-60HI system windows can also be individually installed as well as applied in aluminium façades. When they are used for filling in a mullion-transom wall, their use in combination with the MB-SR50 HI system with an improved thermal insulation is the most appropriate.

MB-70

MB-70 is a modern aluminium system intended for realizations of exterior architectural building elements requiring thermal and acoustic insulation, such as: various types of windows, doors, vestibules, display windows or spatial structures.

The system profiles have a three-chamber structure. The structural depth of the window sections is equal to 70 mm (frames) and 79 mm (casement), and for doors: 70 mm and 70 mm respectively. Such assumed depths of casement and frame sections give the effect of one surface from the exterior side after closing - in the case of the window, and the facing effect to the surface of casement and frames - in the case of doors. Shape of the profiles allows achieving slender and resistant window and door structures. In the MB-70 system, it is also possible to produce windows with the so-called “hidden casement” MB-70US and the MB-70 “Industrial”, finding its application during modernisations of post-industrial historic and monumental objects.

The MB-70 system is characterized by a very low value of the overall heat-transfer coefficient Uf, thanks to application of the thermal breaks and gaskets. This is of a great significance in the times of increasing demands for the energy management and the environment protection. The value of heat transfer coefficient for constructions of the MB-70 system - depending on the applied profiles and accessories – ranges between 1.5 and 2.39 W/m2K. In this system, the profiled "omega"-shaped thermal breaks are applied, of a width equal to 34 mm (windows) and 24 mm (doors), made from polyamide reinforced with fibreglass. The offered shape of thermal breaks increases the profile rigidity as compared to flat breaks and facilitates the section drainage, ensuring the appropriate thermal insulation in all atmospheric conditions at the same time. The thermal breaks applied in the windows have additional gaskets at the joining point with the sections, as well as tongues dividing the chamber between the internal and external aluminium sections into three parts.

Owing to the application of, among others, thermal breaks of such shapes, it is not necessary to fill the space between them with polyurethane foam or foamed styrene inserts, in order to increase their thermal insulation. The tightness is ensured thanks to using the special gaskets made of two-component EPDM synthetic rubber: solid and cellular, which guarantees its ageing resistance during the long-lasting exploitation, as well as very good thermal insulation. MB-70 is the first system in which this type of material was used for creating the central gasket.

The system allows application of sets of glass panel of the thickness equal from 21 mm to 57 mm in window casements, and from 12 mm to 48 mm in fixed windows and door leafs. Such a wide thickness range of infill guarantees the possibility to apply all typical and untypical glass panels.

A wide choice of colours in the standard palette makes it possible to meet the needs of our most demanding customers.

The MB-70 system forms the basis for solutions featuring enhanced thermal insulation performance, such as: MB-70HI, MB-70US HI and for a curtain wall based on MB-70CW HI windows.

MB-70HI

As a response to ever growing demand for building products featuring high insulation performance there have been designed door and window systems with a thermal barrier MB-70HI, MB-70US HI and a curtain wall based on the MB-70CW HI windows. Their construction is based on well-proven, well developed and highly appreciated base systems, i.e. MB-70, MB-70US i MB-70CW.

The thermal insulation performance of frames of this system is considerably higher than the insulation performance of base systems.

The value of heat transfer coefficient Uf for constructions of the MB-70HI system - depending on the applied profiles and accessories – ranges between 1.11 and 2.3 W/m2K.

Enhanced thermal insulation performance is achieved due to placing special insulating inserts in the central insulating chamber, formed by connecting aluminium profiles with thermal breaks. Thus formed inserts reduce heat transfer through this chamber due to low value of heat transfer coefficient. The central location of inserts additionally limits convection and thermal radiation.

The MB-70HI doors and windows, just like in the case of the base system, find application both in individual assemblies and in aluminium façades. If used as a filling of a mullion / transom wall, it would be best to combine such doors and windows with the system featuring enhanced insulation performance, i.e. MB-SR50 HI.

MB-70SG

CONSTRUCTION DESCRIPTION

Opening windows of the MB-70SG are part of the window and door system with thermal MB-70

of ALUPROF Ltd. This system allows execution of windows with wing profiles that are not visible from the

outside. Therefore, window construction MB-70SG meet the aesthetic requirements so imposed by the

architects and investors, i.e. the difference in appearance when looking from the outside, between the fixed

and opening elements is not visible. The width of the visible window frames and battens' profiles is much

smaller than in the case of the MB-70US. The windows of this type are designed for installation in holes in the

wall and to be attached in the mullion-transom facades.

The MB-70SG, like MB-70 has a very low value of heat transfer coefficient U thanks to the use of special

thermal spacers and gaskets. Window profiles of these systems meet the thermal requirements for material

group 1 according to DIN 4108 T.4. The structural depth is 70 mm in both frames and wing.

Aluminum profiles are three-chamber structure, where the central chamber is isolation between thermal

inserts. The system uses profiled thermal omega shaped inserts made from polyamide reinforced with

fiberglass. Such shape of inserts increases rigidity of the profiles when compared to flat inserts and

facilitates drainage. Windows are glued to the aluminum wing with structural silicone. Gluing is performed by

companies fully trained by structural silicon suppliers. The process is monitored which guarantees the correct

connections. Glazing single-chambered tiered windows are used, in which the outer pane, thick 6 mm only,

should be made of tempered or heat strengthened glass. For aesthetic reasons it is recommended to use

reflective surfaces. The system uses the mechanical support of the lower edges of both internal and external

panes. External pane of the glazing window, in the closed wing position, is additionally secured by an external

swing gasket which is a mechanical protection of the glass against possible falling out.

The connection of the glass with the frame is masked from the inside by strips and swing gaskets, so that

glass sets of high range of thickness can be used. The sections have profiled slots of dimensions that allow

circumferential fittings compatible with EURO standards to be used. Connections of the profiles are made,

as in the MB-70, with minimal treatment, using the supplied aluminum fittings and accessories. Detailed

information on individual connections are provided on the following pages.

The usage in the system of tripe sealing of the space between the wing and the window frame ensures

excellent protection against water and air.

Swing inner gasket and central gasket are made of two-component synthetic rubber EPDM: Solid

and cellular, which provides a very good sealing and thermal insulation.

Compliance with the recommendations outlined in this catalog ensures that the manufactured product will

meet the expectations of users during many years of exploitation.

In case of any questions or doubts, the experts of ALUPROF Ltd. will be more than happy to offer help and

advice.

TECHNICAL DESCRIPTION OF RAW MATERIALS AND MATERIALS AND ADDITIONAL DESCRIPTION

PROFILES' CONSTRUCTION

The profiles used in system MB-70SG are three-chamber profiles where the central chamber is insulation

chamber between thermal inserts.

External section - in order to obtain a very good compatibility with silicon design - it is anodized. Internal

section, however, may be anodized or painted to any RAL color.

GLASSES

In the windows of the MB-70SG system single-glazed units can be used, selected in such a way that the

buildings meet the requirements of heat and standards for the protection of anti-sound facilities and safety.

The outer pane, thick 6 mm only, should be made of tempered or heat strengthened glass (for aesthetic

reasons it is recommended to use reflective surfaces).

Warning! Reflective coatings in combination with colored glass are characterized by low light transmission

which needs to be taken into consideration in the design phase of buildings. Selection of glass should be

made on the basis of analysis of samples supplied by manufacturers of glass.

CONSTRUCTION SILICON BINDER

Outer pane of the insulated glass is glued to the external anodized aluminum section with silicone. All

parameters of silicon, glass surfaces and profiles gluing and gluing procedures must comply with the

requirements and the manufacturer of silicone. Before performing the gluing it is essential to test the

adhesiveness of the structural silicone to surface of the section.

THERMAL INSULATION

Heat transfer coefficient for cross-section corresponds to the window frame material 1 according to DIN 4108

T.4

MB-45

MB-45 is a modern aluminium system intended for designing elements of architectural exterior and interior enclosures that do not require thermal insulation, e.g. various types of partition walls, windows, manual and automatic sliding doors, swing doors, vestibules, display windows, ticket box offices, showcases and spatial structures.

The structural depth of the window sections is equal to 45 mm (frame), 54 mm (casement), and the door: 45 mm and 45 mm, respectively. Such assumed depths of the casement and frame sections give the effect of one surface from the exterior side after closing - in the case of the window, and the facing effect to the surface of casements and frames in the case of doors. Shape of the profiles allows achieving slender and resistant window and door structures.

A very significant quality of the MB-45 system is the possibility to bend the profiles, such as: frames, casements and lacings, what allows creating various types of arches and arch structures.

The tightness is assured thanks to application of special gaskets made of EPDM synthetic rubber, which guarantee the resistance to aging during long-lasting exploitation.

The characteristic feature of this system is its close connection with MB-60 and MB-70 window/door systems. The system versatility and attractiveness are additionally enhanced by the possibility to choose from several solution variants in the case of various structural details, e.g.: sealing of the lower door leaf, sealing of the sliding and swing doors, shape of glazing beads and shape and height of the door threshold. This system is also connected with the structure of mortise door MB-45S.

This system allows application of the sets of glass panels of the thickness equal from 2 mm to 35 mm in window casements and from 2 mm to 26 mm in fixed windows and doorframes.

MB-W86

The new MB-86 window and door series have been designed to offer outstanding insulation properties. It meets the increasing requirements from the legislative and general market demands for the enhanced energy saving construction of new windows and doors. Offered in three varieties ST, SI and AERO it is the first aluminum system to employ silica aerogel, the nanoporous material that has a very high proportion of free void volume compared to conventional solid materials. Its high pore volume, low solid content, and torturous path amorphous structure give rise to low values of thermal conductivity. Therefore the system features the industry leading thermal performance. In addition it also features exceptional rate of profiles inertia that allows for greater windows in size and weight.

Features and benefits:

- large selection of profiles

- newly shaped, extra thick thermal breaks

- multi component central gasket

- glazing strips with additional sealing option

- glazing up to 67,5 mm enabling all types of two chamber glazing, acoustic and security, anti burglary glazing

- large, wire-free glass areas

- appropriate for variety of hardware including concealed hinges

- water draining available in both traditional and concealed options

- highly energy efficient from 0,5 W/m2K

- clean, sharp lines of narrow extruded aluminum framing

- multitude of finish options

Performance:

Air Permeability: class 4, EN 12207:2001

Watertightness: class E 1500 Pa, EN 12208:2001

Thermal insulation window (Uf):

MB-86 ST from 1,3 W/m2K

MB-86 SI from 0,9 W/m2K

MB-86 AERO from 0,5 W/m2K

Resistance to windload:

Class C5 (2000 Pa) EN 12211:2001; EN 12210:2001

MB in a plate

CONSTRUCTION DESCRIPTION

The presented fixing system of windows and doors in composite panels is ALUPROF's Ltd. modern

construction that meets the wishes and requirements of clients, architects, investors and partner

companies. It is a system of aluminum sections that allows easy assembly and fastening of various

types of windows and door systems, MB-45 MB-45S,-59S MB, MB-59SE, MB-59S Casement, MB-

59S PIVOT, MB-60 MB-60 PIVOT , MB-60 U.S., the MB-70 MB-70 U.S. systems in objects made from

different types of composite panels of the thickness' range 60 - 150 mm.

The system has a very simple construction and easy assembly consisting of latching fixing angles and

masking sections in special attachment slats. This is very important in the age of increasing demands

for reduction of time-consuming assembly work. Corner joints of sections are made by cutting the ends

of sections at the angle of 45° and connect with the use of aluminum inserts delivered to the corners.

Compliance with the recommendations outlined in the catalog ensures that the assembly will meet

the expectations of users during many years of operating life.

In the event of any questions of doubts the experts of ALUPROF S.A. are more than happy to offer

advice and assistance.

TECHNICAL DESCRIPTION OF RAW MATERIALS AND MATERIALS, AND ADDITIONAL INFORMATION

ALUMINIUM SECTIONS

Aluminium Sections are made in the plastic processing of aluminum alloy EN AW-6060 according to

PN-EN 573-3, T66 condition according to EN 515 or from alloy AlMgSi0, 5 F22 according to DIN 1725

T.1.

Sections meet the requirements of BS EN 755-1.

The mechanical characteristics are in accordance with BS EN 755-2.

Dimensional tolerances of sections according to EN 12020-2.

Surfaces of the sections should be finished with anodic coatings or polyester powder coatings, used

as protection against corrosion.

Anodic coatings should meet the following requirements:

- thickness determined in accordance with BS EN ISO 2360 or ISO 2808 - 20-30 microns,

- the external appearance consistent with PN-80/H-97023,

- the degree of seal coating according to PN-90/H-04606/02,

- resistance of the coating to corrosion according to PN-76/H-04606/03.

-

Polyester Powder Coatings:

- the relative hardness according to PN-EN ISO 1522 - min. 0.7,

- thickness determined in accordance with PN-EN ISO 2360 lub PN-EN ISO 2808 – 75±15μm,

- resistance to detachment from the substrate according to PN-EN ISO 2409 - grade 0,

- resistance to salt spray according to PN-ISO 7253,

- resistance to liquids according to PN-EN ISO 2812.

Choose from more than 180 colors of paint according to RAL marking.

GASKETS

Glass and swing gaskets are made of synthetic rubber EPDM according to DIN 7863 or thermoplastic

elastomeric TPE and standards according to DIN 7715 or ISO 3302-1 E2. Gaskets are combined in the

process of gluing or welding.

MB-59S CASEMENT

The MB-59S CASEMENT system is intended for production of tilt windows and windows opening outwards – the economical ones and possessing good functional qualities at the same time.

This type of windows is intended to be mounted both in wall openings and in mullion-transom facades. The construction is based on the window/door system with a MB-59S thermal break. The structural depth of the window sections is equal to 50 mm for frames and 59 mm for casements. The profiled "omega"-shaped thermal breaks of the width of 16 mm and 22 mm, made from polyamide reinforced with fibreglass are applied.

The windows opening outwards may be equipped with two kinds of hinges: rotational and shear-type. The MB-59S CASEMENT system window sections have profiled grooves of dimensions allowing application of enveloped hardware and connecting elements in accordance with the European Union standards. The hardware mounted therein is produced by reputable companies such as Sobinco and Securistyle.

The system allows application of the set of glass panels of the thickness from 4.5 mm to 40. 5 mm in window casements and from 4.5 mm to 31.5 mm in fixed windows. The structures based on this system are characterized by both high aesthetics and the good functional qualities:

- the surfaces of internal frame and the casement lie in one plane,

- window gaskets are barely visible form the outside,

- gaskets are mounted in a continuous manner, without cutting in the corners, what significantly shortens the mounting time and improves the tightness,

- each structure has an effective water drainage and ventilation system from the glass chamber and from the chamber between the casement and the frame.

The windows opening outwards, basing on the standard window/door system, were created mainly for the users in Great Britain, who are willing to use such type of solutions. However, we are convinced that the MB- 59S CASEMENT structures will turn out to be attractive also in the Polish market.

MB-59S PIVOT, MB-60 PIVOT

The pivoted window MB-59S PIVOT is a part of the window/door system with thermal break MB-59S of ALUPROF S.A. Company.

The MB-59S PIVOT system is designed for producing windows of vertical or horizontal rotation axis requiring thermal and acoustic insulation, economic structures, but also having good functional qualities. This type of windows is intended to be mounted both in brick wall openings and in mullion-transom facades.

The dimensional range for window casements:

1.Window with a horizontal rotation axis:

- Height: 800 - 2000 mm.

- Width: 500 – 2400 mm.

- Weight: max. 180 kg.

2.Window with a vertical rotation axis:

- Height: 500 - 2400 mm.

- Width: 800 – 2000 mm.

- Weight: max. 120 kg.

The rotary hinges ensure the casement rotation angle from 0o to 180o. Hinges may be optionally equipped with a blockade of the casement opening up to the angle equal to 22o. After turning the blockade knob, the window casements can be rotated by the angle of 180o in order to e.g. wash the exterior window surface in a convenient and safe way.

The glass panels or other in-fills are mounted with the help of glazing beads and gaskets. The window structure allows application of sets of glass panels of the thickness equal from 4.5 mm to 31.5 mm.

The tightness against water and air is assured thanks to application of special gaskets made of EPDM synthetic rubber. The window tightness is highly influenced by maintaining a great precision while processing and mounting the structure.

Each rotary window to be mounted in exterior building must be provided with an efficient water drainage and ventilation system from the glass chamber and from the chamber between the casement and the frame. Such type of windows is especially often applied in the countries of the Western and Northern Europe.